Choosing the Best Oil Storage Tank Manufacturers in 2025

Let's be real. When you’re ordering a giant steel tank, you're not just buying material; you're buying decades of liability. If that tank fails—due to a bad weld, cheap steel, or a poor coating—the fallout isn't just a repair bill. It's an environmental disaster, a regulatory nightmare, and a massive hit to your company's reputation. That's a burden that lands squarely on your desk.

That’s why finding the right Oil Storage Tank Manufacturers is one of the most stressful, yet crucial, decisions you’ll make this year. With new tech, tighter environmental rules, and constantly shifting standards in 2025, how do you sort the true engineering experts from the budget chop shops? This guide cuts straight to the practical questions you need to ask to protect your investment.

Who Are You Really Hiring? Understanding the Manufacturer’s Job

Think about it: the Oil Storage Tank Manufacturers you choose become your partner in risk management. They aren't just fabricators; they are highly skilled engineers and problem-solvers. The best ones are obsessed with things the average person never sees, like:

- Weld Integrity: Ensuring a seam won't crack under internal or external stress years from now. This isn't just about passing initial inspection; it's about holding up under fatigue.

- Corrosion Battle: Designing a system that fights the slow, insidious death by rust from the inside out. They know coatings are temporary and plan for the long game.

- The Foundation: Giving you the exact specs to build a stable base that won't shift and compromise the tank walls. Get this wrong, and nothing else matters.

If a manufacturer is vague about these details, they’re probably cutting corners. Period. The top Oil Storage Tank Manufacturers view their tanks as high-integrity pressure vessels, not just big metal boxes. That dedication shows up in their paperwork—the certifications, the schematics—not just their sales pitch.

The Three Deal-Breakers: Certs, History, and Future-Proofing

You can filter your choices down quickly by focusing on these three non-negotiable areas. If they fumble any of these, save yourself the trouble and move on.

1. Show Me the Paperwork: Certifications That Actually Matter

Forget the glossy brochures. Demand proof of certification. In this business, those letters mean everything. Look for manufacturers who actively use and are audited under:

- API Standards (especially API 650): This is the industry gold standard for large, field-erected welded tanks. If they don't have it, they aren't serious. It means they follow rigorous rules for design, material choice, and construction.

- ISO 9001: This tells you they have a reliable quality management system—meaning their processes are consistent, traceable, and audited. This prevents costly surprises during installation.

These aren't just badges. They are proof that a reputable third party verifies their ability to build safe infrastructure.

2. Where Have They Built Before? Experience is the Best Teacher

You want a manufacturer who has been around the block, sure, but specifically, you want one who has built tanks like yours. Ask them directly:

- "Have you built a tank for this specific commodity?" Storing crude oil requires different linings and venting than storing jet fuel or wastewater. Specific experience prevents costly, fundamental design mistakes.

- "What’s your track record in our climate/region?" Building a tank in the humid Gulf Coast is totally different from building one in the dry, seismic West. They must know the regional quirks and local codes without you having to teach them.

A manufacturer who can show you a portfolio of successful, complex jobs similar to yours offers instant, priceless peace of mind.

3. Compliance: Are They Ready for Tomorrow’s Rules?

Environmental regulations are only getting stricter. You can’t afford to install a tank today that will be obsolete—or illegal—in five years. The best Oil Storage Tank Manufacturers are already integrating advanced safety features like:

- Advanced Secondary Containment: Beyond the legal minimum, are they designing systems that truly simplify leak monitoring? This is where good engineering saves you environmental reporting headaches.

- Sustainable Design: Are they choosing materials and methods that reduce long-term maintenance and footprint? This aligns with modern corporate governance goals.

A forward-thinking manufacturer acts like a vital shield, protecting your business from the inevitable fines and regulatory headaches of the future.

Don't Get Caught on the Hook: Beyond the Price Tag

We all have a budget, but in tank procurement, chasing the lowest price is practically begging for a disaster. Focus on the value of longevity.

A tank that costs 15% more upfront but uses superior welding techniques, thicker steel, and specialized anti-corrosion coatings will save you a fortune in maintenance, repairs, and premature replacement over its 30-year life. Cheap manufacturers cut corners on the things you can’t easily see: the purity of the steel, the thickness of the coating, and the skill level of the certified welders. Don't be fooled by a low bid.

The Post-Sale Reality Check: What happens the minute the tank is installed? You need a manufacturer that offers killer customer support. If your pump piping has an issue during commissioning, how fast can you get an engineer on the line? A responsive warranty and quick technical support are crucial. Demand references from their service department, not just their sales team.

Frequently Asked Questions

What's the difference between API 650 and API 620?

Simply put, API 650 is for atmospheric tanks, which are what most people use for bulk oil storage. API 620 is for tanks that handle slightly higher internal pressure. Your engineer will specify which one you need, but most Oil Storage Tank Manufacturers should be certified for 650.

Do I really need to hydrotest the tank?

Absolutely yes. Hydrotesting (filling the newly built tank with water) verifies two things: the tank's structural integrity under full load, and its precise calibration volume. It's a non-negotiable final step before the tank goes into service.

How long should I budget for the manufacturing and installation process?

For large, custom-built tanks, the process can easily take 6 to 12 months—factoring in design, material procurement, fabrication time in the shop, and final on-site erection. Plan way ahead, because lead times only seem to get longer!

What's the biggest cause of tank failure that I can prevent?

Foundation failure and corrosion. You prevent foundation failure by ensuring the base meets the manufacturer's engineering spec. You prevent corrosion by choosing the right internal coatings and religiously maintaining your cathodic protection system.

Conclusion and Your Next Step

Finding the right Oil Storage Tank Manufacturers is a strategic decision that requires due diligence and a laser focus on long-term risk reduction. Make your choice based on verifiable quality, proven experience, and a manufacturer who proactively designs for safety and future compliance.

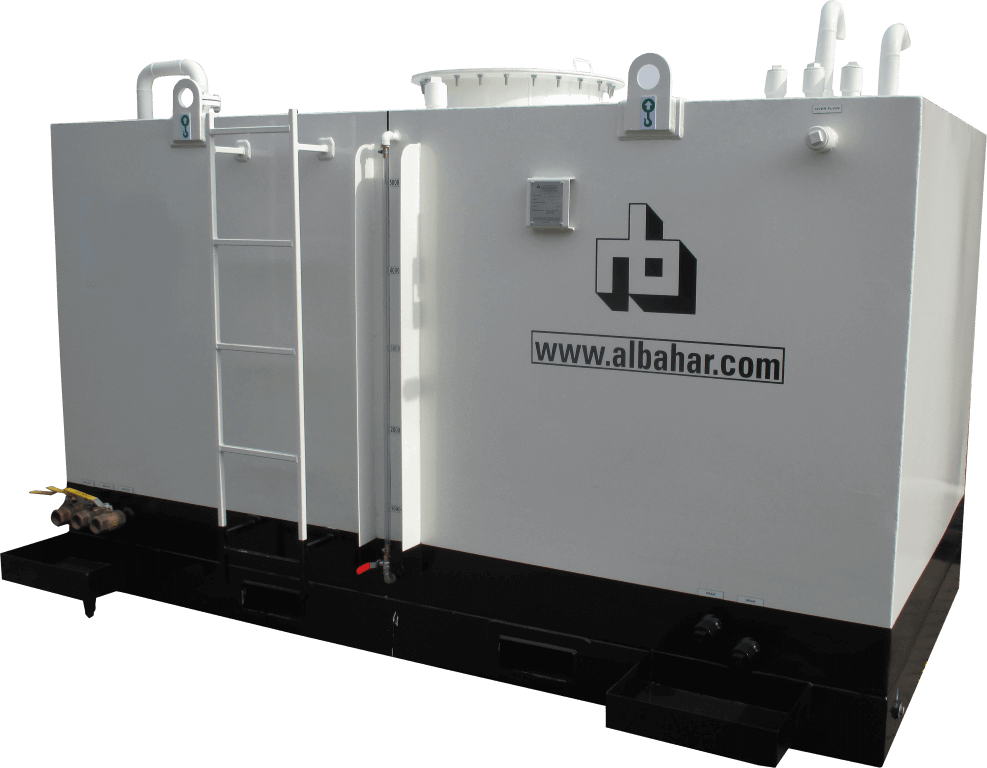

But the protection doesn't stop with the tank itself. The pumps, meters, control panels, and sensitive electronics that manage your fluid transfer operations also need a defense system. That’s where Al Bahar MCEM comes in. Al Bahar MCEM specializes in Metal Cabinets & Enclosures Manufacturing, providing custom-fabricated, robust metal solutions designed to secure and protect all that expensive operational gear around your tank farm. By partnering with Al Bahar MCEM, you ensure that both your valuable oil and the vital systems that control it are shielded by industry-leading, durable enclosures.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness